projects

-

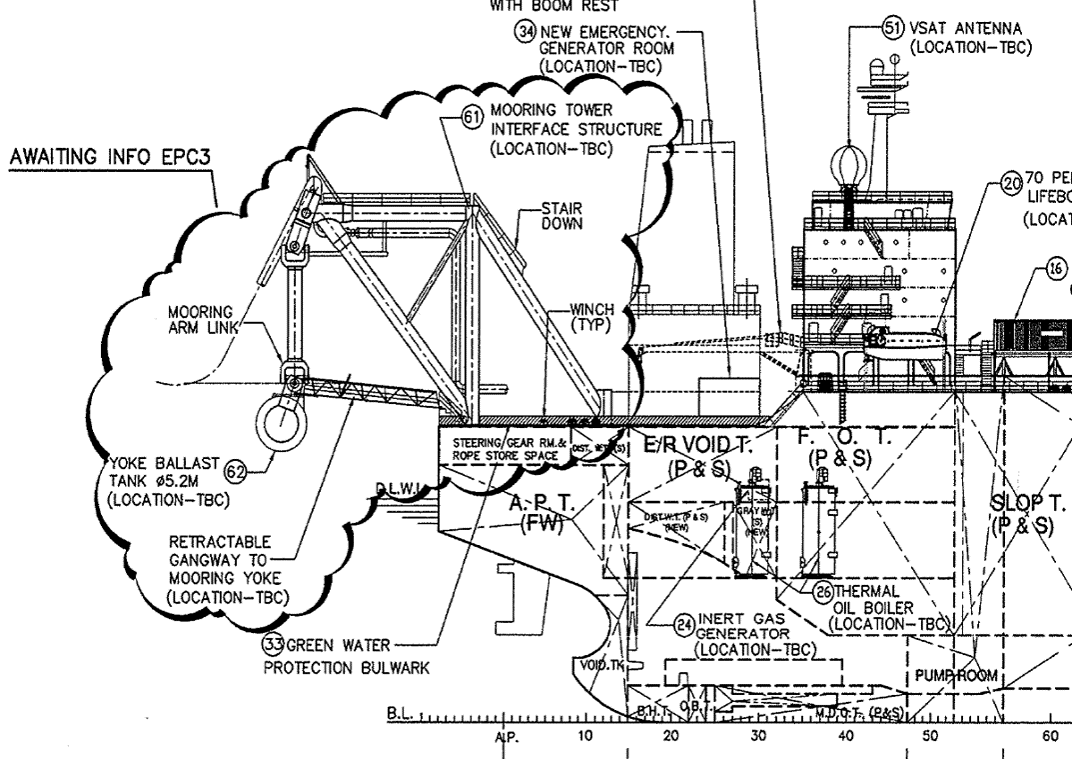

Working Armour has worked on several projects across the Asia Pacific region involving the management of health & safety risk in complex upstream and downstream construction (in oil and gas facilities and shipbuilding) projects conducted across many countries. This has required development of an understanding of local regulatory processes as well as client standards to allow appropriate systems development. Cultural understanding and of the approach to WHS risk has been essential in determining appropriate strategies for effective implementation across multiple countries to allow ever improving performance outcomes.

-

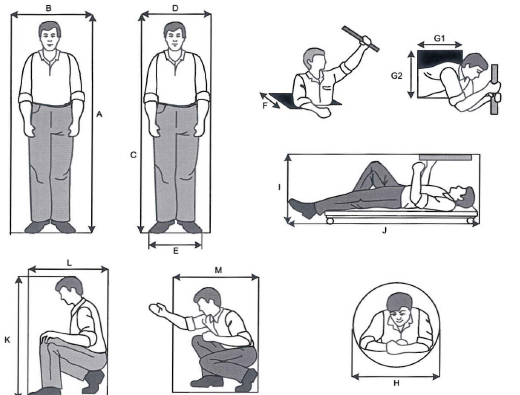

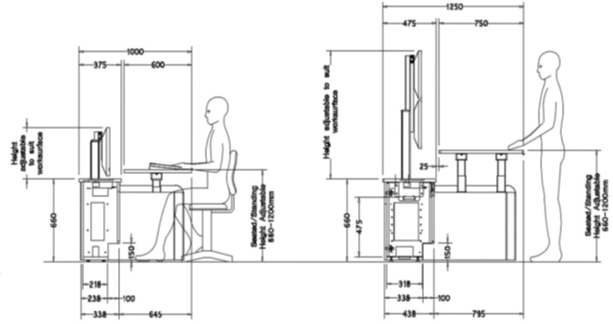

Since 2015 Working Armour Principal has been working with Australian Government Agencies and its previous iterations on the development of technology to allow automated border controls providing human factor risk input to the device lifecycle from design, prototype development, selection, installation, operation, maintenance and upgrade to allow an appropriate trade-off between maximising security whilst minimising border processing time. This has involved an appreciation of the human-machine interfaces, biometric limitations, ergonomics of people traps, behaviour screening, cultural background of travelers, their fatigue, airport logistics and border officer training.

-

Analysis and review of common features in law enforcement, first responder Post Traumatic Stress Disorder. From 2014-Present, Julie Has been involved in providing expert legal opinion from a health & safety perspective related to the prevention and management of PTSD in first responders and others working in high risk industries where trauma exposure is likely due to their need to respond to such incidents in the workplaces. This has ranged from awareness, information and training provided to those potentially exposed with the right level of detail and those in such roles to ensure they will be equipped to deal with the potential effects should symptoms emerge which remain persistent. This has expanded to other industries and has progressed to analysing and reviewing the presence of all other psychosocial risks ranging from work pressure, to bullying & harassment to fatigue.

-

This involves a practical application of legal processes to weaknesses in current management system process based on an operations own incident and risks management failures to then workshop the required improvements. Conducted across heavy industry ranging from mines to construction operators but has also progressed into a number of other sectors with higher fatality profile risk including forestry, environment protection, national parks,agriculture, tourism, transport, hospitality, health & community services

-

This project involved developing an incident reporting system for those in the industry to report anonymously to Safe Work Australia. This was for the purposes of better understanding why these injury & fatality risks were not being effectively managed to reduce the number and incidence of injuries and fatalities in the logging and sawmilling industries across Australia. This required consultation with key stakeholders including separate state and territory union and employer bodies as well as government regulators and individual operations of all business sizes. The system was introduced to the industry and the findings from the 6 month trial was then forwarded to the industry to both recommend the requirements for such a system but also to feedback findings of the risk controls which were failing and why.

-

This involved the following 5 step process: a Review incidents including near misses and their investigation findings for work related travel, a review current of controls, conducting audits to check for compliance and effectiveness; benchmarking internally and externally to identify improved controls; implementing control strategies and process changes to reduce risks; & reporting on findings. This specifically involved the review of 5 years of high potential incidents which could have resulted in a faultity. Root cause analysis was conducted a small number of these were then workshopped with the parties involved to determine why they didn’t result in a fatality and what needed to be carried out to better management the obvious risks represent be they ranging from issues related to the vehicle being used to fatigue, to health, to communications, emergency response processes. The scope included those staff and contractors driving a vehicle provided by the agency, being a passenger driven in an agencyA provided vehicle, travel to and from work in an agency provided vehicle, short turnaround from a night shift or night call out event and driving in the dark as a result of late night or early morning start to work It results found that despite heavy vehicle light truck and utilities making up 75% of the agency fleet, the risk exposure related to the hours of exposure as would be expected. It highlighted that the vast majority of risk controls were administrative in nature and they had not been evaluated for effectiveness. In addition it was determined that most incidents had no investigation conducted with those that were, were primarily addressed by a tools box talk which did not seem to stop similar incidents from recurring, for controls related to drivers not looking or making poor decisions- the controls recommended made no difference to the risk.

-

For 10 years, Working Armour principal audited shipyards in Singapore to provide feedback to the regulator to ensure operators were capable of maintaining their operating licenses. These shipyards ranged from mid size to those employing upwards of 16000 workers on sites approximately 2 km square. The high risk industry had the highest fatality rate of any industry which was turned around by this process where the majority of foreign workers had no common language on the sites. They were literally exposed to almost every high risk hazard known ranging from radiation to hazardous chemical, hazardous dusts, fumes, significant fire and explosion risks, diving risks, height risks, material handling risks, mobile and fixed plant risks, electrical risks, laser risks, hazardous manual tasks, traffic risks, demolition risks, confined spaces, welding, abrasive blasting, confined space, asbestos & lead, diving and other risks related to walking around water..